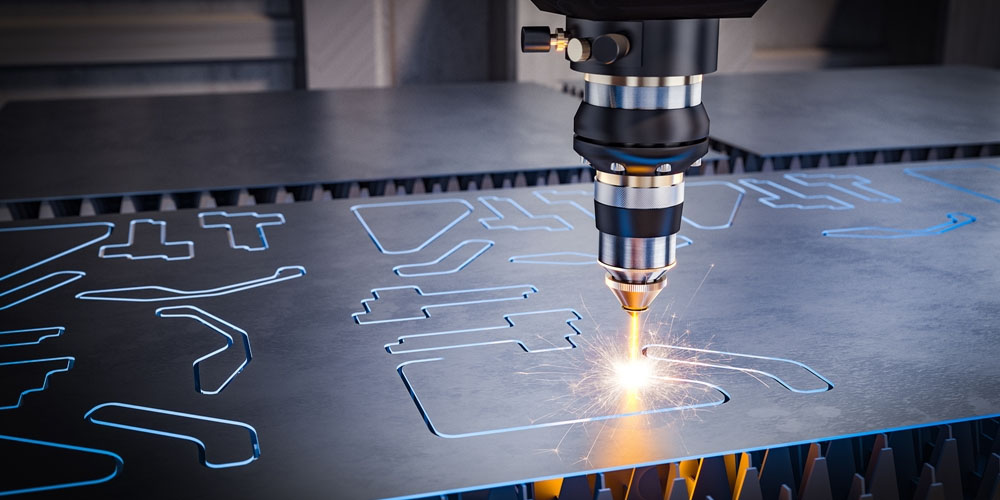

CNC machining is a subtractive procedure done to create different objects. A CNC shop has the necessary machinery to make high-precision parts from various raw materials to suit multiple applications. Manufacturers use special tools like grinders and drills to ensure the end product is in the desired shape and is also fit for the market. The demand for CNC machining technology has increased over the years, considering most industries use it. We discuss the applications of CNC machining below.

Applications of CNC Machining in the Manufacturing Industry

CNC machining is of great importance, and it’s challenging to locate an industry that doesn’t have such a center. Some of the industries using the technology are;

1. Aerospace industry

It is a delicate industry, dealing with very high precision parts. CNC machining technology comes in handy to form metal components for aircraft that can withstand environmental elements, high altitude, pressure, and weight. A vast selection of engineering metals is suitable for use with this technology, thereby providing producers with multiple options for part production. Examples of components produced include landing gear, engine mounts, and fuel flow components

2. Automotive industry

The CNC machining process produces products from different materials depending on the application. Materials like plastics and metal are staples in the automotive industry, taken through several processes before part production. Extruded metals like steel and aluminum are used to make parts like valves, gearboxes, and cylinder blocks.

Parts such as dashboards, gauges, switches, and dials are developed from plastic material. Manufacturers use CNC technology to create standard car parts; however, the same technique can be used to create custom-made components based on the customer’s needs

3. Defense industry

The military and defense industry relies on CNC machining to develop reliable, rugged product parts. The industry’s activities occur in various environments, so the ability to withstand wear and tear is crucial. Every object made must work well in different terrains and have low upkeep.

CNC technology helps develop things like transport gear, airplane parts, electronic parts, and tools for communication. Mostly, some of these parts are made from metal since its durable and can be mixed with other metals to make them corrosion-resistant.

4. Oil and gas industry

Like the defense industry, this sector requires durable and corrosion-resistant parts. Also, they need to be reliable and with high precision to function as desired. The CNC machining process is suitable for creating objects like valves, cylinders, rods, and pistons. These parts are usually leak-proof for safety purposes.

5. Medical industry

The medical industry requires accurate and precise tools for proper diagnosis. One significant benefit of this technology in the industry is how fast the production process is. Speed is a key component in medical practices to give necessary treatment in a short time. The technology allows for the production of machine parts, implants, surgical instruments, monitoring, and orthotic devices

Bottom line

Some industries have used CNC machining for many years, and it’s finding its way in more and more sectors. Modern technology helps industries be at par with all new trends and remain relevant in the market. CNC machining is applied for various reasons, but it generally helps make part production easy, fast and safe for use.