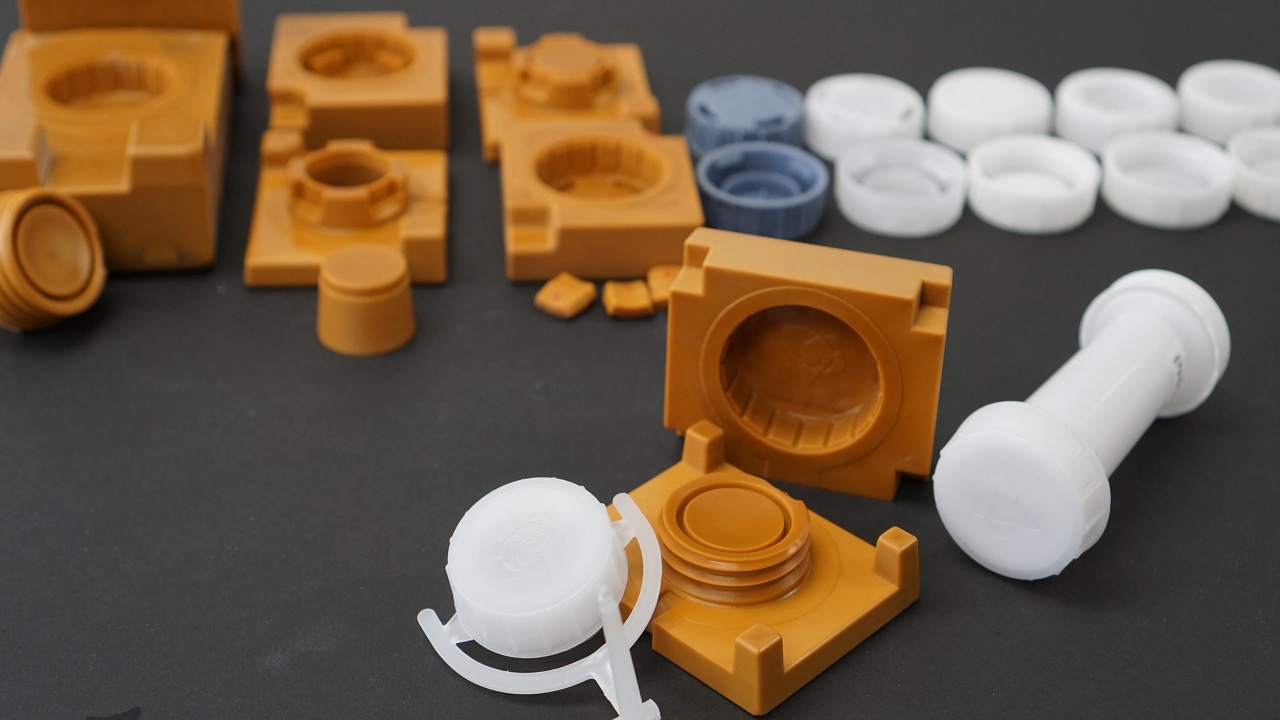

When it comes to the world of injection molding, producing high-quality plastic components is just one part of the equation. Ensuring that these components reach their destination intact and in optimal condition is equally critical. This is where effective shipping and delivery strategies come into play. In this article, we’ll explore the essential considerations and best practices for ensuring the safe transport of injection molded parts.

The Importance of Proper Shipping and Delivery

Injection molding produces precise and often delicate parts. Any mishandling during transportation can result in damage, defects, or increased production costs. Here’s why shipping and delivery should be a top priority:

Protecting Your Investment

Injection molding involves significant time and financial investments in tooling and production. Ensuring safe delivery protects this investment.

Maintaining Quality

Quality control measures are in place during production, but those efforts can be in vain if parts are damaged in transit. Proper shipping helps maintain the quality of the finished products.

Meeting Customer Expectations

Customer satisfaction is paramount. Late deliveries or damaged parts can lead to unhappy customers and harm your reputation.

Essential Considerations for Safe Transport

To achieve safe transport of injection molded parts, it’s crucial to consider various factors:

Packaging Materials

Choose packaging materials that provide adequate protection against potential hazards during transit. Foam inserts, bubble wrap, and custom-designed packaging can help safeguard delicate parts.

Stacking and Orientation

Properly stack and orient parts within packaging to minimize the risk of damage. Avoid placing heavy items on top of delicate components.

Secure Fastening

Use secure fastening methods to prevent parts from shifting during transportation. This may include zip ties, adhesive foam, or custom-designed packaging inserts.

Moisture Control

Depending on the material used for injection molding, moisture control may be necessary. Moisture-absorbing packets or desiccant bags can help protect parts from humidity-related issues.

Temperature Sensitivity

Some materials used in injection molding can be sensitive to temperature fluctuations. Ensure that the transportation environment is within the specified temperature range.

Choosing the Right Shipping Partner

Selecting the right shipping partner is a crucial step in ensuring safe delivery. Consider the following factors when choosing a shipping provider:

Experience with Delicate Items

Look for a shipping provider with experience handling delicate and high-value items. They are more likely to have the expertise needed to transport injection molded parts safely.

Insurance Coverage

Ensure that the shipping provider offers insurance coverage for the value of your parts. This provides financial protection in case of loss or damage.

Tracking and Monitoring

Choose a provider that offers tracking and monitoring services. This allows you to keep a close eye on your shipment’s progress and address any issues in real-time.

Customs Expertise

If your parts are being shipped internationally, ensure that the shipping provider has expertise in customs procedures and documentation to avoid delays and complications.

Proper Documentation

Accurate and comprehensive documentation is essential for the smooth transportation of injection molded parts. This includes:

Shipping Labels

Clearly labeled packages help ensure that they are handled correctly during transit.

Customs Documentation

For international shipments, ensure that all necessary customs documents are complete and accurate to avoid delays at customs checkpoints.

Instructions for Handling

Provide clear instructions to shipping personnel regarding the fragile nature of the parts and any special handling requirements.

Conclusion

Safe and efficient shipping and delivery of injection molded parts are integral to the success of any manufacturing operation. Proper packaging, orientation, moisture control, and temperature monitoring are essential considerations to protect your investment and maintain product quality. Choosing an experienced shipping partner with insurance coverage and tracking capabilities further enhances the reliability of your supply chain. By prioritizing safe transport, you can ensure that your injection molded parts arrive at their destination intact, meeting customer expectations, and upholding your reputation in the industry.