Sheet metal bending is a procedure that uses force to change a sheet metal’s shape. It is done to ensure that one can get the shape or form they want during the production process. Additionally, sheet metal bending uses external force to change only the external elements of sheet metal. The best thing about sheet metal bending is that it applies to various sectors of the economy. Thus, this post aims to update you on the different sheet metal bending applications.

The Different sheet metal bending applications

1. Automotive industry

In the automotive industry, sheet metal bending is essential. Modern-day cars require significant attention, especially in how they look. Thus, panel corners are made with a particular radius that assists in developing visual consistency. Furthermore, sheet metal bending ensures that driver’s and passenger’s safety and aesthetics are prioritized. Some of the parts made through sheet metal bending include; fenders, doors, and hoods.

2. Architecture

In architecture, sheet metal bending helps in shaping metal into various intricate or straightforward shapes. For example, the bending process can help develop curved and arched surfaces that can give off a curvy element and a harmonious structure. Furthermore, sheet metal bending can help create unique structures depending on an architect’s design. The sheet metal bending for architects is quite beneficial as it does not limit the shapes produced.

3. Aerospace industry

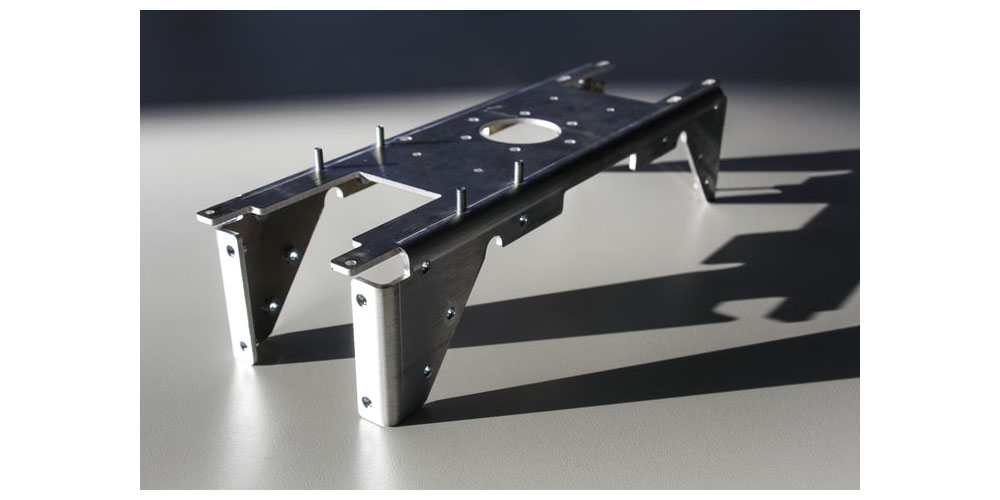

Precision is crucial in the aerospace industry. Additionally, durability and part toughness are also essential. Thus, sheet metal bending comes in handy in the aerospace industry. Sheet metal bending manufacturers develop military and passenger aircraft parts using titanium and aluminum alloy. The titanium alloy and aluminum alloy are very flexible. Thus, they can be used to develop curved features like; engine mounts, fuselages, and wings.

4. Food industry

In the food industry, sheet metal bending is essential in making some of the necessary equipment, such as cans for canned food and cooking pots. Furthermore, the bending process ensures that the industry is supplied with different equipment shapes based on the manufacturer’s requirements.

5. Home appliance sector

Home appliances are the most common sheet metal bending application. The home appliance sector consists of necessities in every home. Thus, the sheet metal bending process ensures that essentials such as cooker hoods, freezers, and sinks are developed in different designs. Furthermore, the home appliances made through sheet metal bending meet their use and are quality.

6. Materials used in sheet metal bending

Different materials are suited differently for bending. Furthermore, most of the materials used for bending are not brittle but are malleable. Some of the most common materials used for bending include;

- Copper: Easily bendable

- Aluminum 5052: Easily bendable

- Mild steel: Can bend at various temperatures

- Alloy steel 4140: Annealing is required first before bending

- Spring steel: Annealing is required first before bending

- Bronze: Difficult to bend

- Titanium: Difficult to bend

- Aluminum 6061: Difficult to bend

- Brass: Difficult to bend

Conclusion

Sheet metal bending is crucial for almost all the essential sectors of the economy. It ensures that bent sheet metals are unique and quality. Furthermore, different materials can be used for sheet metal bending.