3D printing is quickly becoming commonplace in the modern world of technology. Its promise of quick access to almost any 3-dimensional object is what makes it so popular. From large scale precise manufacturing of heavy-duty machine parts or tools to 3D printing pens that are designed to allow toddlers to express their imagination in 3 dimensions.

3D printing is beginning to play a big role in the way we create and innovate. You may be interested in 3D printing as a business opportunity, or maybe you just want a new hobby. Regardless of why you are going to be 3D printing, you will be sure to benefit immensely from this technology. However, there are a couple of things to note before getting started.

- First of all, you need to figure out why you’re 3D printing. The reason you’re going into 3D printing is vital because it will define other decisions you take. For instance, knowing why you are 3D printing will have a great effect on how you print.

If you are printing mechanical parts and tools, you have a specific type of printing technique and material that will serve that purpose. And you can expect that if you are 3D printing for fun or as a hobby, the techniques and materials you will use will be quite different.

If you are printing for business purposes, it would mean that you would print much more than if you were printing for personal use or for fun and the materials and equipment you would buy would reflect that.

- Next, you need to figure out what to print. Not all objects and structures function best when 3D printed, while others are best produced by 3D printing, because of the flexibility and precision that comes with 3D printing. When you decide what object you want to 3D print, and its purpose, you will need to select an appropriate technique and material to print with.

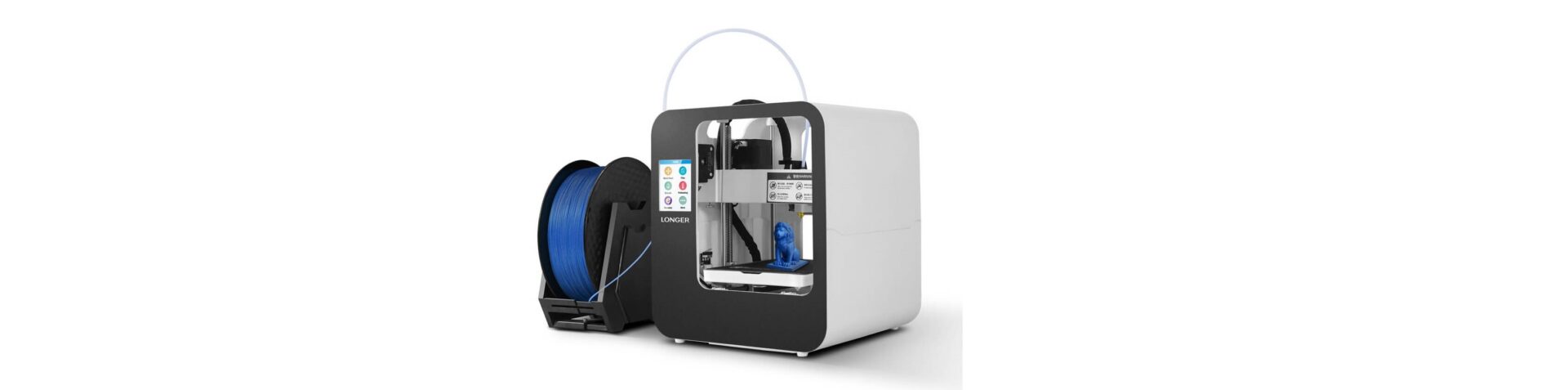

- How to print. There are different 3D printing techniques, and each of them exists as a result of its strengths in certain areas. However, all of these techniques also have their weaknesses. A very popular method of 3D printing is known as FDM which is a Fused Deposition (Modelling). This technique involved melting a filament and extending the preference shape in a step by step manner, from the bottom to the top. Stereolithography produce objects from resins that harden when exposed to light.

These are the techniques usually used for relatively simple and small scale prints. Creality DIY 3D printers are recommended in particular for these types of printer. You also have Selective Laser Sintering (SLS) and Selective Laser Melting (SLM). These techniques involve great precision, and as you might have guessed expensive equipment. These techniques are usually reserved for complex or heavy-duty prints. SLS uses a powdered polymer material, while SLM uses powdered metal.

Other important factors also come into play when making choices about 3D printing. How much money are you ready to spend on this production process? How much time are you willing to invest? Might other fabrication processes meet your needs? All these questions need to be answered before choosing which printer to commit to.