In modern manufacturing, CNC service is one concept that keeps popping up now and then. What exactly is CNC all about? How important is CNC in the manufacturing industry? What are the basic roles of a CNC machinist?

All these and many more will be discussed below to enable beginners to understand more especially the basics.

What is CNC Machining?

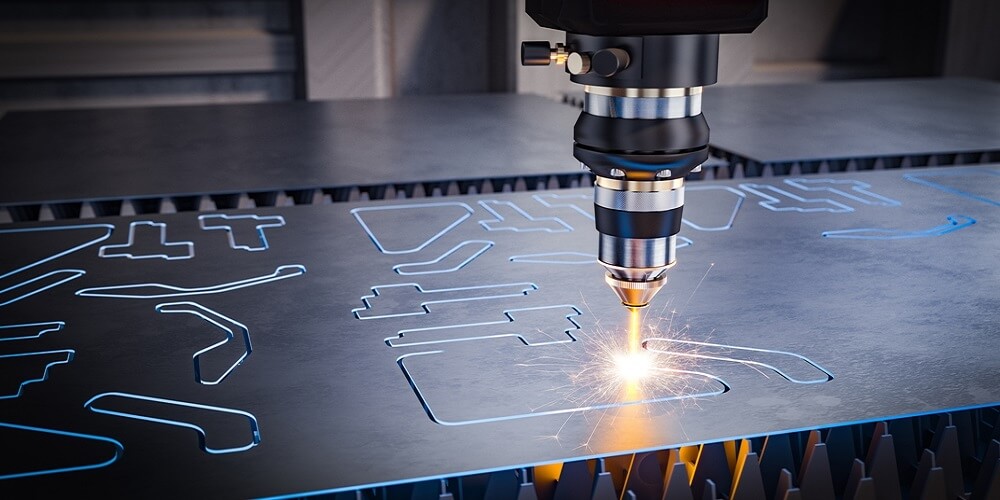

CNC is an acronym that means Computerized Numerical Control. It is a sort of manufacturing process that utilizes software. This software is pre-programmed and directs the activities of the production apparatus.

CNC Machining consists of various sophisticated machinery including turning mills, grinders and, lathes. All these parts play essential roles in the creation, cutting, and shaping of various prototypes and parts.

The normal day-to-day activities of a CNC machinist entail combining elements of technical drawings, computer programming, mechanical design, and mathematics.

This combination of these is used in the manufacture of different metal parts as well as plastic parts. A CNC Mechanist can convert a metallic sheet into a useful automobile or airplane part.

What is a CNC Machine?

A CNC machine is an automated machine operated by computers carrying out pre-programmed sequences. Unlike the “old school “machines that are manually controlled, the CNC machine is designed to be mechanically automated.

The latest CNC machine uses a certain type of machine code called G-code. Thus machine language tells the system the exact measurement needed for production to ensure accuracy. It specifies the location, feed rate, coordination, and speed.

The machine’s mechanical measurements are first defined using computer-aided software. It is later translated by computer-aided manufacturing software into the required manufacturing procedures.

Importance of CNC Machining

Today the importance of CNC Machining in modern manufacturing cannot be overemphasized. It is particularly essential in the production of submarines, jet engines, and helicopters.

With the emergency of CNC Machining, the world can now finally say goodbye to the days of gritty factory life.

CNC Machining prefers manufacturers the opportunity to work with a neater and more advanced technology.

Getting Started as a CNC Mechanist

The CNC industry is a growing industry. Those who wish to venture into this field should be ready to work hard at all times. There is never a dull moment in this field, as every operator is expected to have their hands-on at times.

With adequate training, operators and mechanists help in the manufacturing of various metal products. These products are of great value in the manufacturing industry and hence they contribute immensely to the economy.

Even before the production is completed, a highly trained CNC machinist sees a product at different levels of production. CNC Machining demands creativity and innovation to back up the hard work

Basic Functions of a CNC Machinist

Below are the basic functions of a CNC mechanist

- Reading and interpretation of blueprints, frameworks, and CNC software.

- Setting up, and disassembling both automatic and manual tools, including the machine tools.

- Inspection of machine s feed and speed

- Drilling, turning, grinding, milling, and precise shaping of machine parts.

- Examination and testing of finished products for early detection and correction of defects.

Conclusion

CNC milling machine is an automatic machine and very different from the conventional mass production machine. This difference is what makes them peculiar and as a machinist, you should know this much.