War may be heck or great for definitely nothing, depending upon whether your social references hark back to General William Sherman or Edwin Starr, but army development has a lengthy track record, ultimately, of making private life much better. Whether it’s microwave by way of radar, the web né Arpanet, or the EpiPen influenced by Cold War-era auto-injectors, lots of military applications have transitioned from the field of battle to the house front with welcome results. While 3D printing doesn’t fall into that category, purely speaking, the U.S. Army Combat Capabilities Development Command Army Research Laboratory (ARL) is pushing the technology ahead in manner ins which may jump-start some exciting business applications. ARL has actually developed an additive manufacturing innovation generating dual-polymer components that will certainly allow soldiers to swiftly exchange out broken plastic get rid of durable, 3D-printed replacements, according to a current short article from the Army News Service. The modern technology might be deployed as soon as this year.

3D printing replacement auto components, as opposed to keeping a comprehensive stock, has been just one of the possibly totemic applications of 3D printing. It has been discussed for several years yet never ever really emerged at the auto mechanic’s. ARL believes it has discovered a method to 3D print long lasting replacement components for weapons, and that also might be great information for road warriors. Part of the secret sauce is a dual-polymer filament that combines acrylonitrile butadiene styrene (ABS) with polycarbonate (COMPUTER).

Traditional filaments contain a solitary thermoplastic, as well as the resulting parts are fragile, a non-starter on the battlefield. The product deposits like a warm adhesive weapon, Dr. Eric Wetzel, ARL’s research area leader for soldier materials, told post author Thomas Brading. The layers don’t really bond– by the time a new layer is added, the previous one has cooled down. “Our technology … enables us to make use of standard desktop printers, yet then use post-processing to drastically enhance the sturdiness and also stamina in between layers,” said Wetzel.

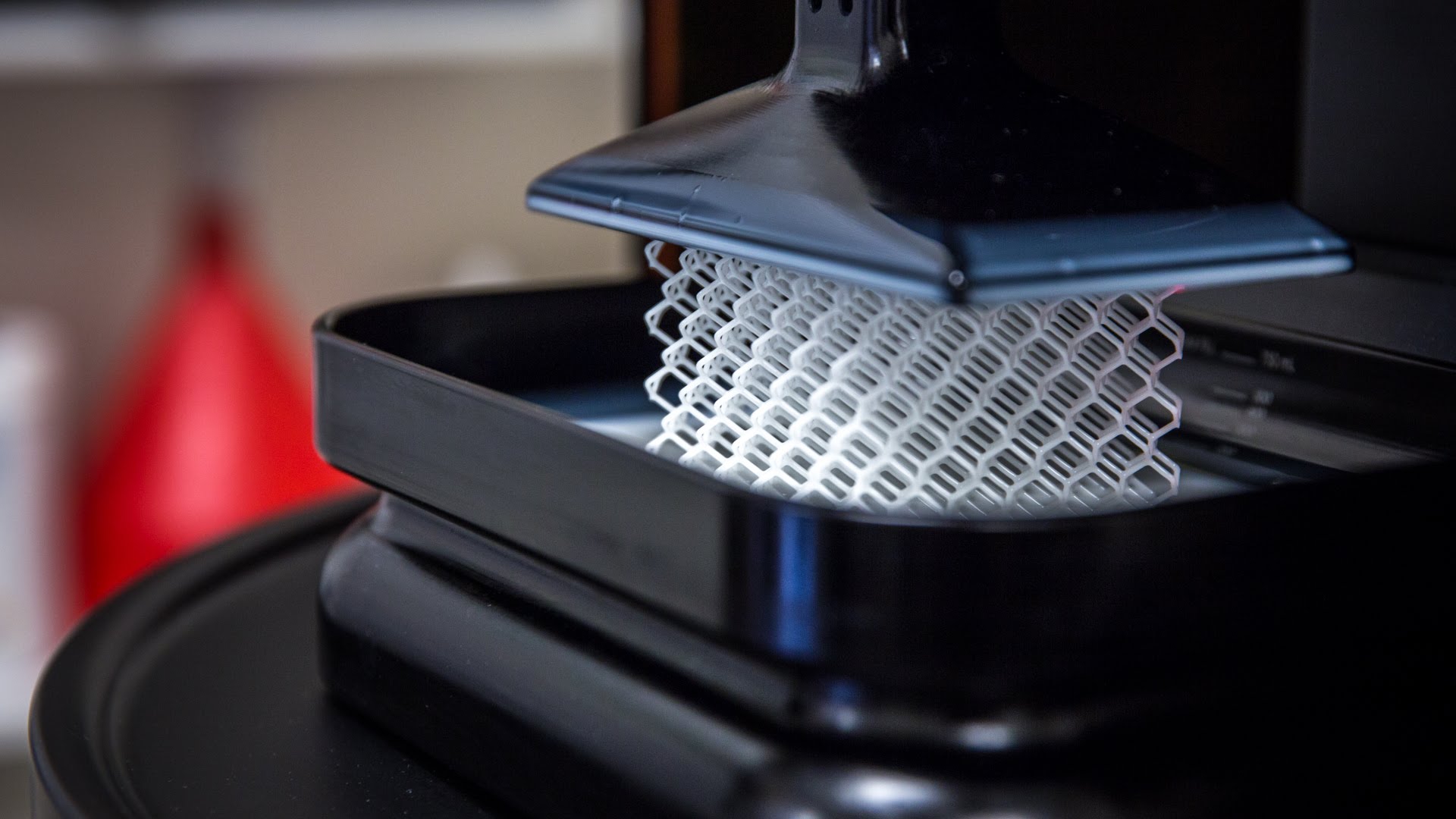

” An essential design function of the filament is that the ABS and COMPUTER phases are not merely mixed with each other, a common method for developing mixed polymers. Instead, an unique die-less thermal illustration process developed by ARL is made use of to produce an ABS filament with a star-shaped PC core,” composes Brading. Scientist picked the star shape following a collection of design tests that revealed it caused the very best mix of part durability as well as stability.

When printed, the parts are annealed. The two polymers have unique melting temperature levels, as well as during the annealing process, the layers of the material fuse with each other while preserving their geometry and also form. Stability is enhanced by the greater temperature level resistance of the integrated structure.

” Manufacturing at the point-of-need offers some interesting opportunities,” stated Wetzel. “In the future we can imagine soldiers released overseas working together with engineers in the United States, allowing new equipment principles to be created and afterwards sent as electronic documents to be exchanged physical prototypes that the soldiers can use the very same day.”