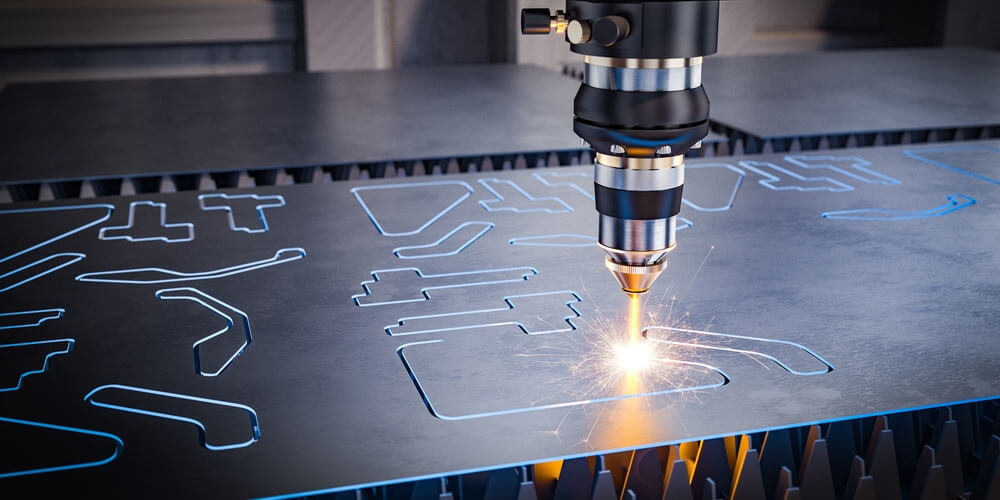

Computer Numerically Controlled (CNC) machining is known for making the production process faster and easier. They also guarantee timely production of quality products. With all these pleasing abilities, it may not be easy to purchase CNC machining China that easily. All these useful features it possesses come with a price tag to pay. It may include;

1. The material quality of used

Having a CNC machining means having one machine that undertakes all the production processes. It means instead of purchasing five different machines to complete five production processes, one can go for a CNC that has combined all these processes. It means the size will be a bit larger to take care of all the compartments required.

The quality of materials used for CNC machining is of high standards to withstand the production process. The high standard of materials used will be expensive, resulting in the general price of the CNC machining being high.

2. Technology used

A CNC machine uses advanced technology to operate; therefore, manufacturers may have to engage more than one professional to develop the final CNC machining. The professionals will be those working to fixe the compartments and the other for installing the computer programs.

We all know how expensive computer programs are. All the involved professionals will have to be paid for their service. In a way, they are all contributing to the high prices of CNC machining. Some industries may have to import technology professionals.

3. Shipping fees

Most countries, especially third-world countries, are not in a position to manufacture CNC machining. Some may have to import them, meaning more expensive on shipping and border clearance fees. As a heavy-duty machine, the shipping fees may even exceed the cost price. But since it’s a necessity, the cost may be worth it.

4. High maintenance costs

CNC machining requires a high voltage of power to operate. It automatically calculates too high electricity bills at the end of the month. In case of breakdowns definitely, CNC machining servicing professionals do not come cheap. Their charges usually are high, considering servicing professionals are usually few.

Further, in case of breakdowns, replacing CNC machining is very costly as you may have to import the parts. Operating a CNC machining will require skilled personnel to oversee the smooth running of the machining. To employ skilled personnel, you will have to part with a reasonable sum of money per month to afford them. Employing unqualified personnel may cost you the CNC machining as they may tamper with the programs.

5. Time spent to assemble the machining.

CNC machining is involved, thus requiring time to assemble the different parts. Like we have seen, it involves more than one professional, which means one has to wait for the other to finish before fixing their parts.

The one fixing the computer programs cannot fix it simultaneously by fixing the compartment and body. The assembling process requires a lot of care and time to ensure perfect machining is gotten at the end.

Final Thoughts

CNC machining is generally for commercial purposes. Whichever country they are taken, there is a need for clearance by the government and a license to permit operation. It includes other government agencies such as those concerned with the protection of the environment. CNC machining may cause noise pollution or emit harmful fumes to the environment. If you are not cleared, you may have to deal with endless lawsuits and even be banned from operating within that country.