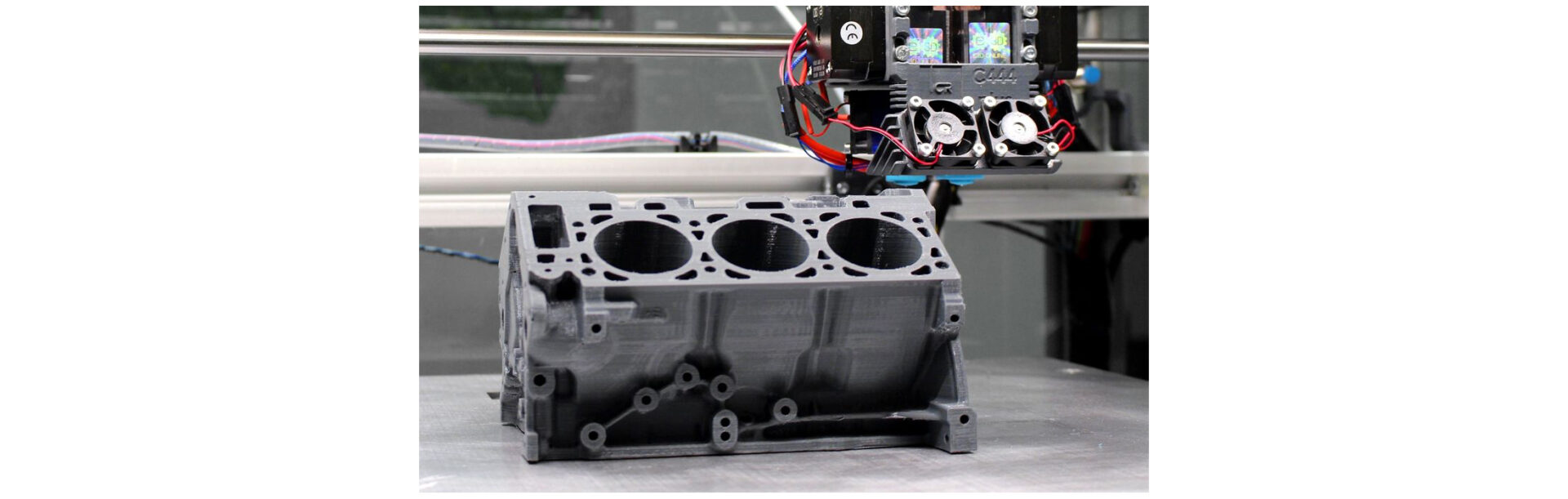

Additive manufacturing, like the name implies, adds material to design an object. It uses 3D form scanners or data CAD (computer-aided design) software to direct hardware to place material, sheet by sheet in perfect geometric shapes to create an object. For example, instead of sculpting a piece of work off a solid chunk, additive manufacturing creates the part sheet by sheet from material provided as a fine powder. Faster market reach, material efficiency, less time, and design flexibility are a few reasons more, and more industries are turning to rapid manufacturing. 3D printing and rapid machining are examples of applications of additive manufacturing.

Additive manufacturing can also be referred to as freeform fabrication, additive fabrication, layer manufacturing, or additive processes. Below are some major setbacks in the slow but progressive adoption of additive manufacturing.

a. A limited range of materials coupled by High cost of material

The materials currently used in additive manufacturing are limited in availability, resulting in high costs. For example, in the aviation industry, just a small set of polymers plus metal powder is used to manufacture aircraft parts.

These materials are highly-priced compared to the materials used during traditional manufacturing. This high cost reduces the incentives to apply additive manufacturing in the production process.

b. Property Inconsistencies of Materials

There are plenty of inconsistencies in the printable 3D materials’ general properties with the limited availability of materials. The industry currently lacks a dependable database of materials with defined specifications and proven parameters.

c. Size limitations

Assembling odd-sized and large parts is one of the major weaknesses of additive manufacturing. Additive manufacturing underperforms to a great extent in this sector compared to traditional manufacturing.

d. Slow production processes

Many additive manufacturing industries still lag when it comes to mass production, like those operating under mass production of consumer and automotive goods.

These industries must manufacture and deliver products in as short a period as possible. Speed is obviously of great significance in this case. Additive manufacturing will ultimately get there, but it currently still faces this problem.

e. Manual Post Processing

At the moment, post-processing is a key limitation to establishing additive manufacturing production lines. For metal additive manufacturing, post-processing steps involve removing the powder properly and passing the object through a stress-relieving heat cycle so that the parts do not get warped and distorted from the heat stress.

Plenty of time is needed to cut and grind away the supporting structures because these are largely manual processes.

f. Scalability Limitations

When there’s a sudden rise in demand, scaling up production may not be possible to current additive manufacturers. This scalability limitation can be solved when additive layering systems produce different parts simultaneously or where producing and unloading are done concurrently.

g. Quality Inconsistencies

Additive manufacturing still experiences challenges with quality consistencies at the moment. For example, the quality properties of some materials assembled in additive manufacturing still don’t add up to quality tolerance levels of some companies, like aerospace companies.

h. Absence of Digital Infrastructure

Companies require the proper digital infrastructure to carry out their additive manufacturing processes efficiently. Usually, these solutions are designed with the specification of traditional manufacturing taken into consideration and are not always optimized for additive manufacturing workflows.

Final Thoughts

Additive manufacturing has many shortcomings, but as technology constantly advances, so will the process. In the past decade, the industry has made significant steps ahead by developing faster and better systems, indicating more growth and advancement in the years to come.