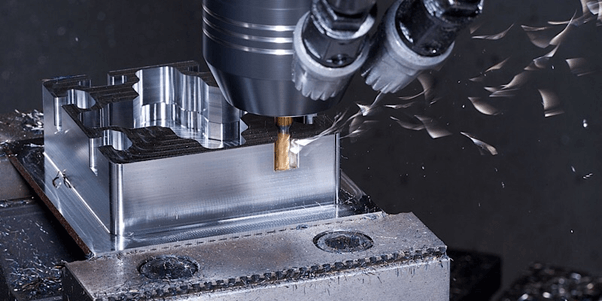

The manufacturing of products is currently more efficient in different sectors that rely on milling aluminum. Besides, the goods are also standardized thanks to the immense growth and development of the CNC processes. But, for these processes to vividly run smoothly, and for the machines and other equipment involved to the last longer, you need to select the right CNC machine coupled with a reliable brand that is highly revered for quality. To achieve that, you must have useful qualities at your fingertips. Here are some of the critical areas you should not miss out on evaluating a proper CNC aluminum machine and how to reduce the actual CNC aluminum Cost.

The radius of the machine

When selecting an aluminum CNC machine, you need to choose one that shall go beyond the total maximum area for the products you intend to produce. An ideal example would be; if you aspire to purchase gun drills, then you need to select one that has a slightly bigger working radius as compared to the largest material that you shall cut.

The Availability Of Spare Parts

As with any appliance, any CNC machine can break down at any moment. Of course, this is usually with uninterrupted use. You need to make sure that the technicians can repair the brand you select from the market. You also need to rest assured that these spare parts are available in the industry. This availability highly eliminates the downtime between the moment the machine broke down, and then time it is back on and functioning correctly.

Precision Selection

There are about 20 precision inspection elements for every CNC machining center. Most of the components checked include single-axis positioning, accuracy, and the roundness of the piece produced using the simultaneous machining of the two axes.

Power Consumption

Depending on the type of machine and equipment you buy, you may have to increase the available power in your workshop. Consider checking the power demands and requirements of the machine in order to be in a position to make the necessary adjustments at the machining center.

What’s more, you need to know that CNC machines are costly by all means. So, it would only be reasonable and prudent of you to make a viable decision based on the type of projects you will be handling. Here, we imply that your decision should be influenced by the magnitude of the projects you are currently in charge of. Go for something that will last long.

Final Thoughts

Note, the history of product manufacturing dates to the 1950s. Large production machines were launched at that moment. They functioned electronically and were ideal when it came to drilling, milling, in addition to boring. By the look of things, CNC machines are slightly different from the numerical control machines in that they utilize digital codes rather than the manual punch tapes.

But in one way or another, they all serve the same purpose of producing several parts at once. CNC aluminum machines have a significant impact on our world as it allows for mass production of different products to occur in the market. It also makes production cheaper.