Nowadays CNC machining has become more viral and highly used in all industries. Almost all industries rely on this latest technology. From prototyping to mass production, everything is done with this latest technology. But still, some basic-level industries use manual turning to create basic-level tools and components.

This article will allow you to explore the difference between cnc turning parts also turn as CNC machining and manual machining. This discussion is going to be very interesting if you want to know how both of these methods are different from one another and how that is beneficial for the growth of business. Do not miss any single line.

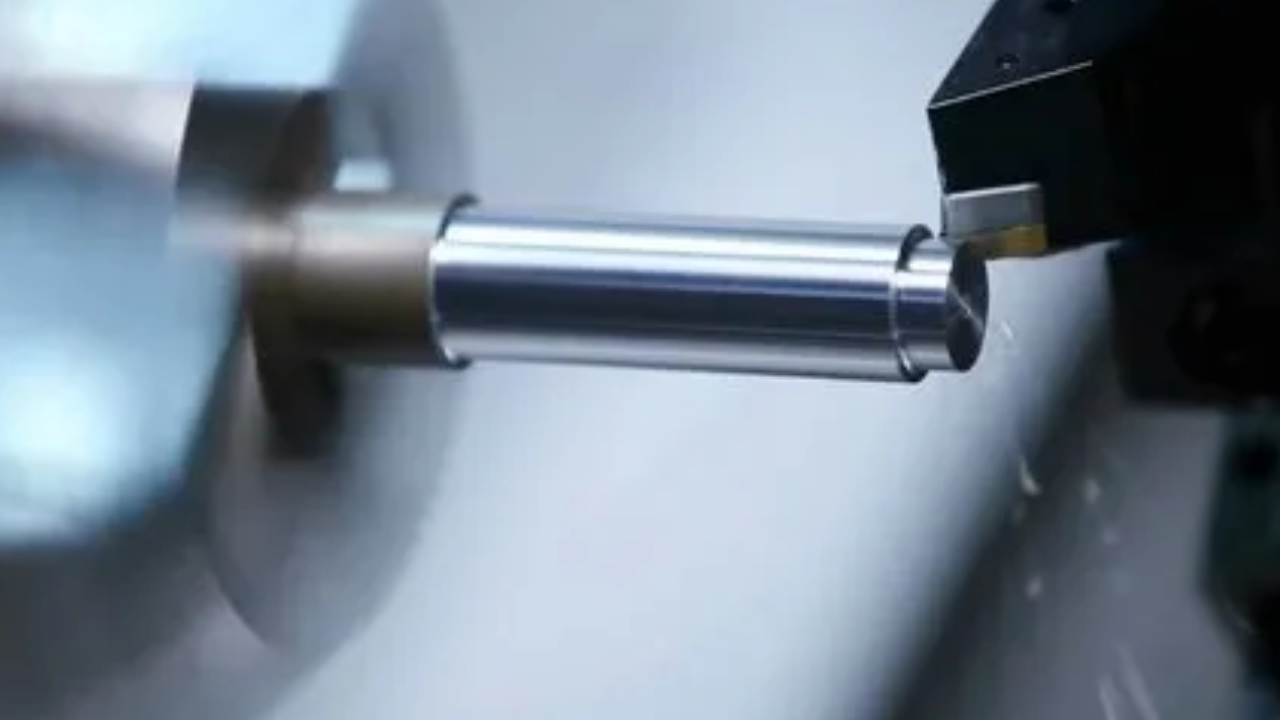

CNC Machining

If you are looking for some advanced options this CNC machine is the best choice for you. This is the latest and the most advanced type of technology that uses special algorithms to provide you with the most accurate and durable outcomes ever. This is the era of technology and working with such type of machinery is the need of the day.

Moreover, it provides scalable processing and exact measurements that you want from your products. Each work from start to end is done with the help of the latest machinery. This technology was introduced in the 20th century and is the biggest innovation of this era that makes everything simpler.

Benefits

- It provides the fastest speed with rapid production

- Due to its first production, the manufacturer removes the deadlines and supplies all the products whenever you want to.

- It is very safe to use because lots of safety measures are involved to protect against all types of damage.

- Latest methods and different techniques are used to provide the finest product ever.

- No human operations are needed for the cutting or creating tools.

- No possible human error can occur; every detail is 100% accurate with zero error.

- It is possible to create highly complex tools and designs as per the desire

Limitations

- It is costly and needs lots of investment.

- It is a type of strange computer design so highly educated workers are needed

- Machine operation may depend on the skills of workers

- In case of any breakdown, lots of money or cost will be needed to fix it.

- It might increase unemployment

Manual Machining

Manual machine is the most common and the simplest type of machining. As its name defines, this is manual. That means human work is involved in this type of machining. Simply human labour and human work need to care for different tools. Moreover, you can make handmade or human-made tools.

The cutting and processing of tools are done with the help of very simple cutters and tools. This process can be simple or complex but it depends on the worker’s skill. Moreover, some human errors are possible in this type of machining.

Benefits

- Very low investment is needed and with low cost, you can start this business.

- There is no need for any programmed machines or a higher level of education for processing.

- Small projects can be done very easily and effectively

- Customization can easily done and tools can easily be changed

- In case of a breakdown, no high cost is needed.

Limitations

- The manufacturing process is very slow and needs lots of time to process complex designs

- Mostly simpler designs are tools made

- Errors can be possible

- There is no large-scale production

Final Words

This was all about the difference between both of these best and highly used technologies. Both have their type of benefits and limitations. Now it’s up to you to select the type that suits you best. Moreover, selecting the advanced options will give you more benefits than the usual ones. If you find this blog interesting, let me know in the comment section.